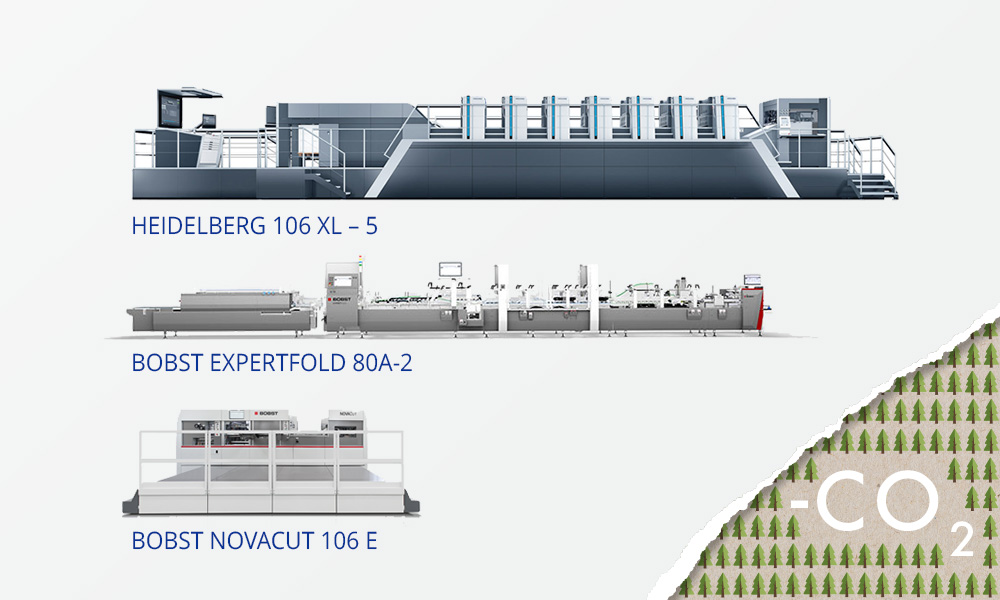

Over the last few months, five new machines have been purchased for the Livorno site, specifically:

- 1 HEIDELBERG 106 XL – 5 printing machine complete with UV oven and Prinect Image Control 4 for colorimetric and graphic control.

- 2 BOBST NOVACUT 106 E die cutters complete with ACCUREGISTER.

- 2 BOBST EXPERTFOLD 80A-2 Folder Gluers.

How can the purchase of printing machines improve the environmental impact and sustainability?

- The HEIDELBERG printing machine is CO2 NEUTRAL certified: that is, its total net emissions are zero.

- The BOBST die-cutting machines are equipped with an energy recovery device. During the slowdown of the machinery, the kinetic energy is converted into electricity: this saves energy costs and reduces CO2 emissions.

- BOBST folder-gluers are Carbon Neutral certified.

HEIDELBERG has always been very active on the front of sustainable products: for this reason it has launched the carbon offsetting project. Purchasing a Heidelberg CO2 neutrality certificate, through the “SODO” project of the NGO World Vision in Ethiopia, near Mount Damota, helps to restore soil fertility, inhibit erosion, rehabilitate springs and increase biodiversity.

With regard to BOBST products, FAVILLINI has chosen the option linked to sustainable development and created in collaboration with the myclimate foundation. It consists of investments in a set of international projects related to the environment which aim to offset the carbon dioxide emitted during the construction and delivery of BOBST machinery with myclimate Certificate.

The management of FAVILLINI – for many years now – has decisively taken the direction of respect for the environment with the FSC®-COC Certification, the use of 100% certified Green energy and the achievement of the EPD Certification for the entire line of packaging.

These good practices have contributed to the confirmation of the EcoVadis Silver Medal 2023 recognition.